Traidenis NV-2 Comfort (1,44m3/d до 8 cilv.) удленнитель, очистное сооружение бытовых сточных вод, био септик, био канализация

NV Comfort is an upgraded NV type domestic wastewater treatment plant where the biological wastewater treatment process is based on the biological and chemical principle. NV Comfort has an added sludge storage capacity to minimize sludge removal and a control system that controls the operation of the unit to ensure high cleaning rates, warns you that the device is not working properly. Control systems thanks avoids many unpleasant things which happens to equipment malfunction.

NV Comfort achieves high phosphorus and nitrogen removal efficiency domestic wastewater cleaning by biochemical purification. NV Comfort type aerobic plants are acting in a biological - chemical way and most often used for treatment of domestic wastewater for private houses. Equipment is installed, where there is no possibility of connection to centralised sewage networks.

NV type biological treatment plants of domestic wastewater are intended for treatment of domestic or similar wastewater from the kitchen, bathroom, toilet and other similar-purpose facilities.

Substances that cannot enter the treatment plant are as follows:

- surface wastewater (off the roof, from the yard, etc.);

- wastewater from a garage and other non-domestic – purpose facilities;

- water from a basin or other receptacles that are larger than 1 m3;

- chemical substances, entering into sewage system of which is not provided according to their usage (oil products, agrochemical substances, etc.);

- water after regeneration of filters of softening/removal of iron;

- chemicals used at home (washing means, bleaches, softeners, degreasers) shall be use as provided in manufacturer’s recommendations.

Advantages

- high degree of cleaning: high organic materials, nitrogen and phosphorus removal;

- factory enclosed biological treatment unit for domestic waste;

- various capacities;

- no internal movable parts to be supervised or replaced;

- durable light plastic construction (easy to ship);

- quiet operation and no offensive odour diffusion;

- treated discharged water – transparent and odourless;

- minimum power consumption;

- no need in auxiliary filtering equipment;

- easy maintenance and process automation;

- easy installation, maintenance;

- due to the sludge compactor supplied, excess sludge removal work can only be performed once every 1-3 years or les.

NV Comfort type biological treatment plants of domestic wastewater meets the requirements of the EU Directive 89/106/EEC and all the provisions of Annex ZA to the standard EN 12566-3:2005+A2:2013 “Small wastewater treatment systems for up to 50 PT – Part 3: Packaged and/or site assembled domestic wastewater treatment plants”.

Notified body: Public company Certification Centre of Building Products (li, Statybos produkcijos sertifikavimo centras, SPSC), Wastewater Treatment Plant Testing Laboratory (li, Nuotekų valymo įrenginių laboratorija), Linkmenų st. 28, LT-08217 Vilnius, Lithuania, notification No. 1397.

The new 5th generation NV Comfort type wastewater treatment plants

About NV 1÷3 Comfort type wastewater treatment plants

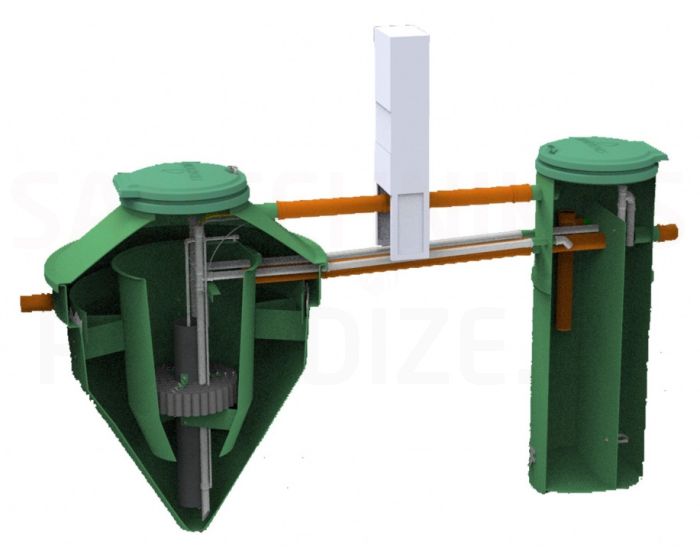

Domestic wastewater treatment system consists of two separate tanks – the NV 1÷3 Comfort type biochemical wastewater treatment plant (Figure 1: I), sludge thickener (Figure 1: II) and control unit box (Figure 1: III).

The sewage primarily flows through the pipe into the receiving/denitrification chamber (Figure 1: II, 11 pos.) from which through the inlet pipeline self-flow passes through the aeration chamber (Figure 1: I, 1 pos.), of the treatment plant, where air assistance is mixed with the activated sludge.

The air is supplied by the air blower (Figure 1: III, 18 pos.) which is necessary for supporting life of activated sludge and internal recirculation of treated wastewater. Blower supplies oxygen continuously.The air through the diffuser (Figure 1: I, 4 pos.) lifting from the bottom to the top, which results, the wastewater is mixed with the activated sludge.

NV Comfort type biochemical wastewater treatment system is based on: Biological treatment and Chemical treatment.

Biological treatment is based on microorganisms activities. Purpose of the process is to bind soluble, colloidal and biogenic substances from wastewater into the activated sludge and separate activated sludge. Flake forming microorganisms multiply and form groups that cause adherence of protozoots and other bacteria. Microorganisms metabolyse (“eat up” and decompose) and destroy organic substances.

Decomposition of organic materials, oxidation of ammonium compounds to nitrites, nitrates, and formation of activated sludge performs in the aeration section.

At the beginning of the plant operation, until the concentration of activated sludge has reached 20% by volume, the removal of phosphorus from wastewater is exclusively biological.

Activated sludge concentration of 30% by volume is achieved within 1 - 3 months depending on ambient temperature.

Circulating nitrified sludge from a biological treatment plant aeration chamber recirculating sludge returning airlift assistance (Figure 1: I, 22 pos.) to fed to a denitrification chamber (Figure 1: II, 11 pos.), where mixer (Figure 1: II, 15 pos.) is mixed with incoming wastewater, during this process, the ammonium nitrogen is oxidized to nitrate and simultaneously the nitrogen compounds are removed from the wastewater.

The return mode for circulating sludge is set in control unit box (Figure 1: III).Air to circulating sludge return pump and mixer is supplied by air blower (Figure 1: III, 18 pos.) through the air distributor manifold.

The amount of air supplied to the mixer is adjustable according to the mode set in the control system. Denitrified wastewater from the receiving chamber flows into the aeration chamber (Figure 1: I, 1 pos.).

If the mass of microorganisms increases, the amount of the activated sludge also increases.

When the amount of activated sludge reaches 30% by volume, for non-biologically removed phosphorus from wastewater to remove to aeration chamber (Figure 1: I, 1 pos.) from coagulent capacity (Figure 1: III, 19 pos.) by the chemical dosing pump (Figure 1: III, 17 pos.) starts dosing the coagulant solution.

Prior to this, it is necessary to determine the concentration of phosphorus in the effluent. The residual phosphorus concentration is used to determine the amount of coagulant and the operating mode of the dispenser. The chemical coagulant used for dry cleaning is polyaluminium chloride PAX118. Coagulation of the dissolved phosphorus compounds takes place upon insertion of this chemical co-agent into the aeration chamber (Figure 1: I, 1 pos.). Coagulated phosphorus compounds are removed with excess sludge. Excess sludge from the aeration chamber (Figure 1: I, 1 pos.) Periodically discharged to the sludge compaction chamber (pos. II, 12) by means of the excess sludge removal pump (I, pos. 21). Air is supplied to the excess sludge pump via a blower (Item III, Item 18) through the air distribution manifold. The amount of air supplied to the excess sludge pump is controlled according to the mode set in the control system.

Mixture of the activated sludge from the aeration chamber (Figure 1: I, 1 pos.) enters the external chamber (the secondary settling vessel) (Figure 1: I, 5 pos.), where, due to gravity forces, the activated sludge separates and falls down into the bottom part of the plant, from which, with the help of aeration system, once again rises into the aeration section – aerotank. Clarified wastewater enters into the collection duct, installed in the perimeter of the whole secondary settling vessel, and by passing through the flow regulator, is removed through the outflow pipe

Excess sludge in the exceeds sludge chamber (Figure 1: II, 12 pos.) falls down into the bottom part of the plant, dewatered water through water overflow trident (Figure 1: II, 14 pos.) enters to the denitrification chamber (Figure 1: II, 11 pos.),

and returned to the aeration chamber (Figure 1: I, 1 pos.). Sludge removal from aeration chamber is carried out according to the factual sludge concentration at least once a week.

The excess sludge is removed from the sludge collection chamber once per 1 – 3 years using the sewage truck (depending on sludge collection chamber volume).